About This Item

UHMWPE Technical Specifications

Denier |

25 | 50 |

75 |

100 |

1200 |

|---|---|---|---|---|---|

| Break Strength (lbf) |

1.5 lbf | 3 lbf | 4 lbf | 6 lbf | 70 lbf |

| Modulus (g/den) | >1100 | >1100 | >1100 | >1100 | >1100 |

| Diameter* | 0.067mm (0.0026") | 0.095mm (0.0037") | 0.116mm (0.0046") | 0.134mm (0.0053") | 0.465mm (0.0183") |

| Elongation | <4% | <4% | <4% |

<4% |

3.5% |

| Filament Count | 17 | 36 | 920 | ||

| Yield (lb/1000 ft) | 0.0018 | 0.0037 | 0.0055 | 0.0074 | 0.090 |

| Yield (ft/lb) | 555,550 | 270, 270 | 181,180 | 142,850 | 11,110 |

*Calculated diameter

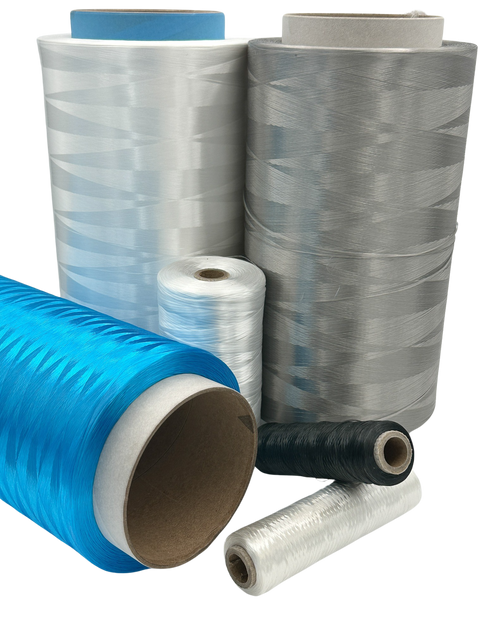

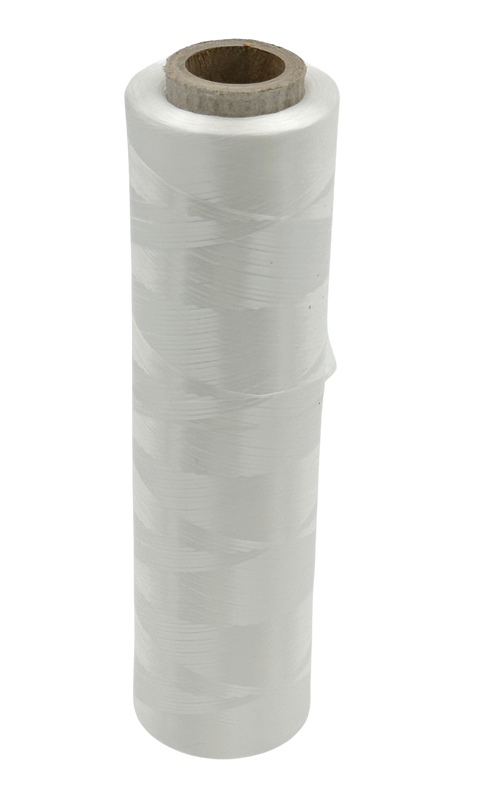

UHMWPE Packaging Details

| Product | Spool Size | Quantity | Tube Dimensions

|

Tube Sizes |

|---|---|---|---|---|

| All Sample Sizes | Sample Spool | 0.25 lb | Standard Tube Dimensions

|

3.7" x 8.5" |

| 200 - 400 Denier | Factory Spool

|

2.0 lb | Standard Tube Dimensions

|

3.7" x 8.5"

|

| 1000+ Denier | Factory Spool | 5.0 lb | Standard Tube Dimensions

|

3.7" x 8.5"

|

UHMWPE Physical Property Guide

UHMWPE fibers such as Spectra® or Dyneema® possess exceptional mechanical properties. They offer an extraordinarily high strength-to-weight ratio, excellent abrasion resistance, and very low moisture absorption due to UHMWPE being hydrophobic. Keep in mind that UHMWPE fibers can creep under constant, sustained loads compared to other high-performance fibers.

UHMWPE Resistance Guide

UHMWPE fibers like Spectra® or Dyneema® offer high resistance to corrosive substances, such as most acids, alkalis, and organic solvents, making them valuable in industrial settings where chemical exposure is commonplace. However, UHMWPE fibers are not without their shortcomings. They exhibit limited thermal stability, which reduces their performance and longevity at elevated temperatures. While their melting point is approximately 135-147°C, they begin to lose their properties around 100°C. Moreover, UHMWPE fibers possess low flame resistance. In a fire or high-heat scenario, they readily melt and burn.

This fiber exhibits poor flame resistance and will melt at 135°C. It is not advisable to use in any application where an open flame is present.

This fiber exhibits poor heat resistance and will melt at 140°C. It is not advisable to use in any application where high heat is present.

Acid: Highly resistant to most acids, maintaining their mechanical properties

Alkali: Withstand exposure to most alkalis with minimal degradation

Organic Solvent: Generally compatible with a variety of organic solvents

Continuous Operating Temperature Range (°C): -150 to 70

Short Term Exposure (°C): 100

Melting Temp (°C):140 - 152

UHMWPE Performance Highlights

- High Strength: One of the strongest synthetic fibers available by weight.

- Ultra Lightweight: Low density allows UHMWPE fibers to float in water.

- Abrasion Resistance: Excellent. Performs well in high-wear environments.

- Low Moisture Absorption: Hydrophobic fiber maintains performance in wet condition.

- UV & Chemical Resistance: Resistant to UV exposure and most acids, alkalis, and solvents.

UHMWPE Properties Table

The table below represents the nominal mechanical properties of industrial grade. UHMWPE. UHMWPE fibers are sold in standard and high-modulus formats tailored for specific applications.

| Property | Unit Of Measure | Standard | High Modulus |

|---|---|---|---|

| Tenacity | g/d | 30.0 - 36.0 | 38.0 - 40.0 |

| Tensile Modulus | g/d | 1000 - 1200 | 1200+ |

| Specific Gravity | ratio | 0.97 | |

| Avg. Elongation | % | 3.4 | 3.1 |

| Moisture Regain1 | % | < 0.1 | |

| Melt Point | °C | 135-147 | |

| Decomposition Temp | °C | Melts | |

| Creep2 | % | 1.7-5.0 | |

| Shrinkage3 | % | Melts | |