About This Item

Kevlar® Braid Technical Specifications

| Product | 70 lb Sea Green |

70 lb Natural |

750 lb Natural |

|---|---|---|---|

| Fiber Type | Kevlar® | Kevlar® | Kevlar® |

| Color | Green | Natural | Natural |

| Coated | ✓

| ✓

| x

|

| Coating Property | + Abrasion Resistance + Color | + Abrasion Resistance | n/a |

| Break Strength

(lbf) |

72.3 lbf | 73.1 lbf | 765 lbf |

| Diameter

(mm, inch) |

0.44mm

(0.017") |

0.44mm

(0.017") |

3.17mm

(0.125") |

| Elongation

(%) |

<3.0% | <3.0% | <4.0% |

| Yield

(ft/lb) |

5,670 | 6,200 | 230 |

Scroll right to see more!

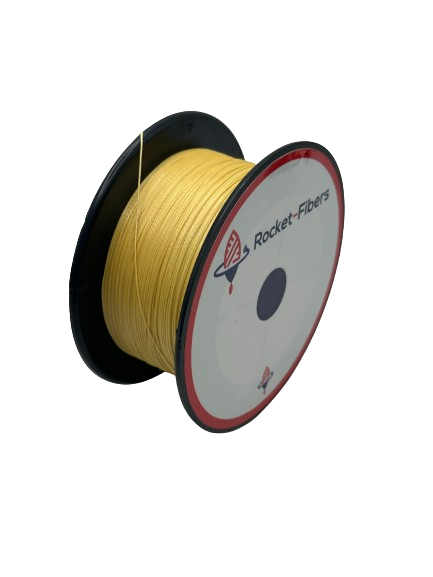

Kevlar® Braid Packaging Details

| Product | Quantity | Spool Type | Tube Size

|

|---|---|---|---|

| 70 lb Green & Natural - Coated | 1000 ft

|

Standard Reel | Standard Reel Dimensions

|

| 70 lb Green & Natural - Coated

|

5000 ft

|

Standard Reel | Standard Reel Dimensions

|

| 750 lb Natural | 100 ft

|

Standard Reel | Standard Reel Dimensions

|

| 750 lb Natural

|

500 ft

|

Standard Reel

|

Standard Reel Dimensions

|

| 750 lb Natural

|

1000 ft | Large Reel |

|

Kevlar® Braid Product Details

- 100% Kevlar® fiber braided construction for maximum strength-to-weight performance.

- Continuous braided line with no splices — one continuous length per reel.

- Abrasion-resistant coating on select products for improved durability.

- Available in multiple break strengths and diameters to suit diverse applications.

- Excellent heat & flame resistance

- Custom lengths and bulk quantities available on request.

Product Performance

- Excellent strength-to-weight ratio makes this braid ideal for applications demanding high load capacity without added weight.

- Good abrasion resistance, especially on coated versions, extends service life in rugged conditions.

- Heat and flame resistance typical of para-aramid fibers like Kevlar®.

- Low stretch and creep under load, maintaining dimensional stability over time.

Kevlar® Braid Suggested Applications

-

Strength members in composite assemblies and hybrid cables

-

Pull cords, actuation lines, and control cables

-

Timing, guide, and reinforcement cords in belts, conveyors, and drive systems

-

Tethers, lanyards, and retention lines for industrial and aerospace use

-

Metal wire replacement where weight reduction and corrosion resistance are critical

-

High-temperature and flame-resistant cordage

-

Sporting, fishing, and bowfishing lines requiring cut resistance and minimal stretch

-

General industrial cordage for abrasion- and fatigue-resistant service

PARA-ARAMID RESISTANCE GUIDE

Para-aramid fibers, such as Kevlar®, exhibit excellent resistance to high temperatures, maintaining their mechanical properties even at elevated temperatures. This heat resistance makes them suitable for applications in thermal insulation and protective clothing. Additionally, para-aramid fibers demonstrate good chemical resistance, enabling them to withstand exposure to acids, alkalis, and many organic solvents without significant degradation.

This fiber will degrade with prolonged UV light exposure. These fibers will brown and weaken over time. Please keep this fiber stored away in a dark room and in the UV protective bag the fiber was shipped in.

This fiber will absorb atmospheric moisture up to 5-7% in weight. This fiber should be stored in a cool, dry room with low humidity. A desiccant bag was included with this fiber to prevent regain during transit and short-term storage at your facility.

Acid: Prolonged exposure to concentrated strong acids will cause degradation

Alkali: Degrades with prolonged exposure to Sodium Hypochlorite

Organic Solvent: Moderate degradation in Carbon Tetrachloride and Ethylene Glycol

Continuous Operating Temperature Range (°C): -40 to 170

Short Term Exposure (°C): 420

Degradation Temperature (°C): 480