When you’re choosing a rope, the options are as varied as the tasks they’re meant to handle. From heavy lifting to recreational use, the right choice makes all the difference in the success of your task. For many, the critical decision lies in choosing synthetic fiber ropes or traditional ropes. This comparison requires thoughtful consideration, as different needs and circumstances necessitate distinct solutions.

Rocket-Fiber’s guide is here to simplify the decision-making process, helping you understand what factors truly matter. By focusing on the key differences, applications, and considerations, you can gain the clarity you need to confidently select the perfect rope for your specific requirements.

Describing Traditional Ropes

We’ve been relying on traditional ropes for centuries. They’re crafted from natural materials such as hemp, cotton, and manila. These ropes are renowned for their straightforward production processes and compatibility with a wide range of everyday applications, from agricultural tasks to decorative uses.

With their natural composition, traditional ropes offer an aesthetic quality that appeals to those seeking simple, timeless solutions. Their familiarity and accessibility make them a dependable choice in contexts where biodegradability and low-cost functionality are primary considerations.

Describing Synthetic Fiber Ropes

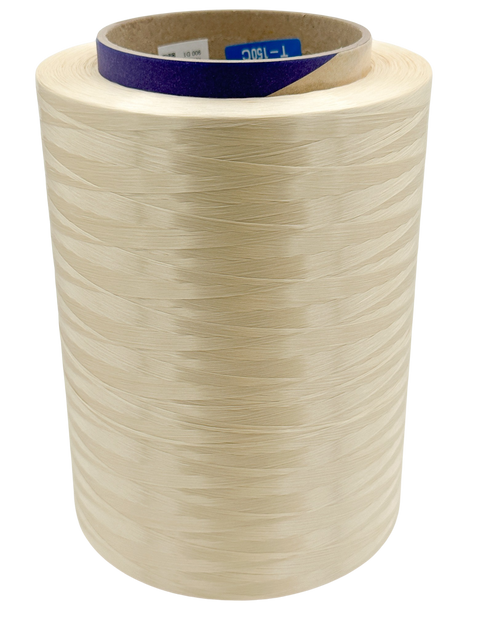

Synthetic fiber ropes represent a modern evolution in rope technology, engineered from synthetic materials like nylon, polyester, and even advanced high-performance fibers. Designed for reliability in demanding environments, synthetic fiber ropes are often associated with innovation and precision.

The versatility of these types of ropes allows them to serve industries ranging from marine and aerospace to recreational activities where specific performance characteristics are essential. Synthetic fiber ropes embody contemporary advancements in materials science and are designed to meet the needs of more specialized and technical applications.

Major Differences Between Fiber and Traditional Ropes

Understanding the differences between fiber and traditional ropes is key to making an informed choice. Here’s a breakdown of their distinctions.

Material Strength and Durability

Synthetic fiber ropes are significantly stronger and more durable than natural traditional ropes. They maintain their integrity even in extreme conditions, while traditional ropes can weaken when exposed to water, sunlight, or heavy loads.

Weight

Synthetic fiber ropes boast a much higher strength-to-weight ratio. This makes them easier to transport, handle, and use in applications where weight restrictions are critical, such as aviation or sports.

Resistance to Environmental Factors

Synthetic fiber ropes are resistant to moisture, UV exposure, and chemical degradation. On the other hand, traditional ropes are prone to rot, mildew, and deterioration when exposed to similar conditions.

Flexibility in Design

Synthetic fiber ropes can be engineered to meet specific application needs, offering flexibility in design and construction. Naturally made traditional ropes are more uniform in their properties and offer limited versatility.

Cost and Accessibility

Traditional ropes are generally more affordable upfront, making them popular for basic, low-cost applications. Synthetic fiber ropes may cost more, but they offer better long-term value due to their durability and performance.

Applications for When To Use Each Rope Type

Understanding when to use synthetic fiber ropes versus traditional ropes depends on the specific needs of your project.

When To Use Traditional Ropes

- Sustainability-oriented projects: Use natural ropes like jute or hemp for biodegradable and eco-friendly needs.

- Temporary applications: For short-term use, such as tying bundles, traditional ropes are a cost-effective option.

- Rustic aesthetic goals: Hemp or cotton ropes are frequently chosen for decorative purposes due to their vintage appearance.

When To Use Synthetic Fiber Ropes

- Industrial settings: Synthetic fiber ropes offer the load capacity, temperature/chemical resistance, and durability required for construction, oil and gas operations, and the aerospace industry.

- Marine environments: Their resistance to water absorption makes UHMWPE (Ultra High Molecular Weight Polyethylene) fiber ropes a preferred choice for boating, fishing, or offshore applications.

- Sporting and safety equipment: Lightweight, high-performance UHMWPE or Technora fiber ropes are used in climbing, parachuting, and slacklining.

Tips for Choosing the Right Rope

You might have an idea of what rope you need at this point, but here are a few more tips to keep in mind when you’re choosing a traditional or synthetic fiber rope for your application.

- Understand the application: Clearly define the load, environment, and frequency of use. Heavy industrial lifting may require aramid fiber ropes, while an aesthetic vineyard project might benefit from a traditional hemp rope.

- Consider environmental factors: Will the rope be exposed to water, UV rays, or chemicals? If so, a durable synthetic fiber rope is likely your best option.

- Evaluate strength requirements: Select a rope with sufficient tensile strength to withstand the weight and pressure of the application. Synthetic fiber ropes typically outperform here.

- Think of longevity: Consider synthetic fiber ropes for long-term projects; their synthetic composition resists wear and tear more effectively.

- Assess grip needs: For applications that require better manual handling, such as farming, traditional ropes may be more comfortable.

Why High-Performance Synthetic Fiber Ropes Are the Future

The industrial world is constantly evolving, and so is its demand for materials that deliver better performance. High-performance synthetic fiber ropes check every box for modern needs, whether that’s increased strength, enhanced durability, or the convenience of lightweight handling.

For industries like aerospace, military, and oil and gas, synthetic fiber ropes and cords provide solutions to challenges that their traditional counterparts cannot overcome. A synthetic fiber rope’s resistance to rot, chemicals, and extreme conditions ensures a longer lifespan and greater reliability in critical scenarios.

If you’re looking to stay ahead, integrating synthetic fiber ropes into your operations can lead to significant improvements in efficiency and reduced maintenance costs. They are not merely an alternative but an upgrade that meets the complex requirements of today’s ambitious industrial applications.

Choose the Best in Synthetic Fiber Rope Innovation

Elevate your performance with Rocket-Fibers' high-performance synthetic fiber ropes, crafted from advanced materials and precision-engineered for unparalleled performance. Whether you need ropes for heavy-duty industrial work or recreational activities, our innovative designs deliver superior strength, durability, and reliability.

Backed by decades of expertise in fiber technology, Rocket-Fibers is committed to providing solutions that meet your toughest challenges. Explore our range today and experience the difference in premium quality.

Both synthetic fiber ropes and traditional ropes have their place. By understanding their unique characteristics and applications, you’ll be better equipped to make practical decisions that align with your goals.

Choosing synthetic fiber ropes or traditional ropes can define the functionality and longevity of your work. If reliability, strength, and longevity are priorities, investing in synthetic fiber ropes is undoubtedly the smarter option.

If you’re considering the switch to high-performance synthetic fiber ropes or have questions about their applications, feel free to reach out to Rocket-Fibers for expert advice tailored to your industry.