When we think about humanity's greatest achievements in space exploration, our minds often drift to rocket engines, navigation systems, and life support technologies. However, one of the most critical breakthroughs in our quest to reach Mars comes from an unexpected source: a revolutionary synthetic fiber that has quietly transformed how we approach space missions. Understanding how Vectran™ changed the game in our journey to Mars reveals the profound impact that advanced materials science has on our ability to explore the cosmos.

What Is Vectran™ and the Science Behind Its Success?

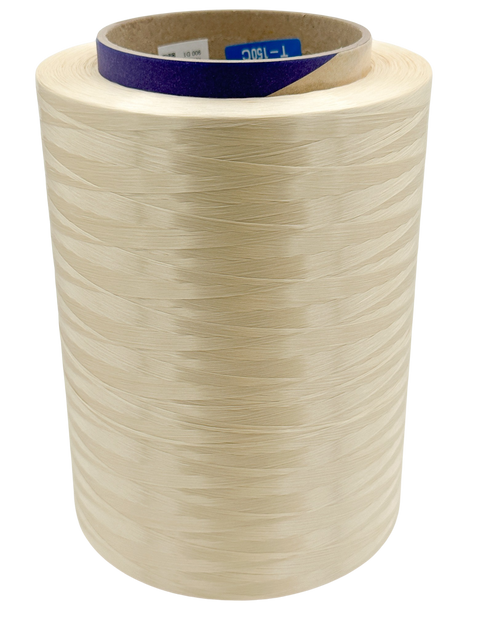

Vectran™ is a high-performance synthetic fiber celebrated for its exceptional strength, durability, and reliability. Designed to excel in demanding environments, this material has become a trusted choice for industries like aerospace. This is because aerospace components must withstand extreme conditions without compromising their integrity. Its adaptability and resilience set Vectran™ apart from traditional materials, solidifying its position as a groundbreaking innovation in modern engineering.

The fiber’s extraordinary properties stem from its advanced molecular structure, which enables it to effectively handle stress and maintain its integrity over time. Vectran™ also retains its performance across a wide temperature range, making it ideal for applications exposed to both intense heat and frigid cold.

Additionally, its natural resistance to radiation ensures consistent reliability in harsh environments, such as the depths of outer space. This unique combination of features underscores why Vectran™ is an essential material for pioneering endeavors, such as Mars exploration.

The Challenges of Mars Exploration

Mars presents one of the harshest environments humanity has ever attempted to explore. Each mission must overcome a series of formidable obstacles, from the unforgiving conditions of space to the unique hazards of the Martian surface.

The Constant Threat of Radiation

Spacecraft and equipment en route to Mars are exposed to intense cosmic and solar radiation. These high-energy particles can degrade materials, weaken structural components, and pose serious risks to mission-critical systems.

Temperature Fluctuations

Mars missions face extreme temperature variations ranging from intense heat to freezing cold. Materials must remain functional and stable across this wide range to ensure both survival during the journey and performance on the Martian surface.

The Challenges of the Martian Atmosphere

On Mars, the thin atmosphere presents unique challenges, such as drastic pressure differences and the risk of equipment damage from frequent dust storms. The surface environment, with its corrosive and abrasive dust particles, further tests the durability of materials.

Why Material Choice Matters

Choosing the right materials is critical to overcoming these challenges and ensuring spacecraft and equipment can perform reliably. Advanced materials like Vectran™ fiber provide the resilience necessary for successful long-duration missions. This safeguards billions of dollars in investments and the success of humanity's next great stride.

How Vectran™ Became a Key Player in Space Missions

Vectran™ first drew attention for its exceptional performance in earth-based applications, where it demonstrated superior resistance to environmental stress. Aerospace engineers quickly recognized its potential for space missions, appreciating its many abilities.

NASA and other agencies began using Vectran™ in mission-critical applications. With each successful application, Vectran™'s role in space exploration expanded. What started as a material for protective covers evolved into integral spacecraft components. Its proven reliability in harsh environments has made Vectran® a vital asset in ensuring the success of current and future space exploration initiatives.

Vectran's™ Role in the Journey to Mars

Vectran™ plays a vital role in numerous aspects of Mars exploration. Here is how this material was a team player in crafting essential mission components.

Landing Systems

Parachutes and airbag systems rely on Vectran™ for its strength and flexibility. These components must deploy flawlessly after enduring months of space travel, ensuring spacecraft and equipment land safely on the Martian surface.

Inflatable Structures

Habitat modules and equipment shelters made with Vectran™ require materials that can expand reliably while withstanding the Martian environment. Vectran™'s dimensional stability ensures these structures maintain their integrity once deployed.

Protective Equipment

Vectran™ is a key material in protective covers for sensitive instruments and electronics. These covers protect essential scientific and communication equipment from Martian dust, temperature extremes, and radiation, ensuring uninterrupted functionality throughout the mission.

Vectran™'s versatility and dependability in these applications are critical to the success of Mars missions, highlighting its significance in advancing interplanetary exploration.

Beyond Mars: The Future of Vectran® in Space Exploration

The success of Vectran™ in Mars missions has opened new possibilities for future space exploration. As space agencies plan missions to the outer planets and their moons, the material's proven performance in extreme environments makes it a natural choice for these ambitious projects.

Deep space missions present even greater challenges than Mars exploration, with longer durations and more extreme conditions. Vectran™'s demonstration of reliability positions it as a key enabling technology for these future missions. Its ability to maintain performance over extended periods makes it essential for missions that may last decades.

The development of space-based infrastructure, including orbital habitats and manufacturing facilities, will rely heavily on advanced materials like Vectran™.

Why Your Business Should Care About Vectran™

The unique properties of Vectran™ make it a valuable asset for businesses looking to enhance product performance and reliability, particularly in demanding environments. Key benefits and applications include:

- Vectran™ provides high strength while remaining lightweight, enabling the creation of durable yet efficient products that reduce fuel consumption, especially in aviation and automotive applications.

- Products that face consistent wear and tear or friction, such as industrial belts and protective coverings, benefit from Vectran™'s ability to withstand abrasion without compromising performance.

- Whether used in textiles or high-tech systems, Vectran™ adapts seamlessly to complex designs, supporting innovation in industries from medical devices to robotics.

- By resisting fatigue and degradation, Vectran™ minimizes the need for frequent replacements, reducing maintenance costs and providing long-term value.

- The durability of Vectran™ makes it a reliable solution for creating longer-lasting products, aligning with sustainability efforts to reduce waste and resource use.

Vectran™ represents a cutting-edge material solution for businesses aiming to innovate and remain competitive in a rapidly evolving market.

The exploration of Mars has ushered in a new era of innovation, and few materials exemplify this progress like Vectran™. It’s remarkable how Vectran™ changed the game in our journey to Mars, demonstrating its unmatched potential in overcoming extreme challenges.

For businesses aiming to harness the power of advanced materials, Rocket-Fibers stands ready to be your trusted partner. With our expertise and commitment to quality, we provide the Vectran™ solutions you need to elevate your products and drive innovation. Connect with us today and take the first step toward building a stronger, more resilient future.