When you examine the most advanced equipment across aerospace, military, automotive, and sports industries, one common thread stands out: exceptional performance under extreme conditions. High-tech equipment—from lightweight aircraft components that withstand tremendous stress to protective gear that shields against electromagnetic interference—must consist of materials that deliver superior strength, durability, and functionality.

The answer lies in precision-cut fibers, which represent a leap away from traditional materials. By offering enhanced properties, this material directly translates to better-performing end products. Understanding why precision-cut fibers are the secret to high-tech gear shows you the bigger picture.

What Are Precision-Cut Fibers?

Precision-cut fibers have exact lengths and dimensions, and manufactures create them using advanced cutting techniques. Regular fibers can vary in size and quality due to standard manufacturing processes, but precision-cut fibers have unique specifications. These fibers are ideal for high-performance applications requiring reliable and strong components.

These fibers usually consist of carbon, aramid, glass, or advanced polymers and play a key role in composite materials. In composites, precision-cut fibers provide the structural framework that reinforces a material and distributes stress evenly. Think of the fibers as tiny building blocks that give materials their strength, flexibility, and durability, whether in aerospace components, sports equipment, or protective gear.

How Precision Cutting Enhances Fiber Performance

Precision cutting improves fiber performance by making each fiber uniform in size and shape. The fiber works seamlessly with others to strengthen a material and make it more durable. By maintaining consistent dimensions, precision-cut fibers eliminate weak points that can occur with irregular or uneven fibers. The resulting material can handle stress without breaking or failing.

Additionally, precision cutting allows manufacturers to control how fibers are arranged and packed within a composite. This optimized alignment improves mechanical properties, such as tensile strength and flexibility, while enhancing resin bonding in composite applications. The result is a material that is stronger, more reliable, and efficient in various environments.

The Tech Behind the Fibers

Engineers create precision-cut fibers using advanced manufacturing technologies. These manufacturers employ laser cutting, ultrasonic cutting, and mechanical cutting to achieve the necessary specifications for high-performance applications. Quality control professionals support these processes by monitoring every stage of production to meet tight tolerances. The result is a product with exceptional surface finish, dimensional accuracy, and mechanical properties. In additionally, it will meet the demands of various industries and applications.

The Unique Power of Precision-Cut Fibers

Precision-cut fibers combine advanced engineering with remarkable versatility. Let’s find out what gives them their unique power.

Strength Without Bulk

Precision-cut fibers deliver exceptional strength while being lightweight and relatively thin. By having uniform dimensions, these fibers can be tightly packed and perfectly aligned to create materials with an outstanding strength-to-weight ratio. This is crucial in the aerospace industry, where reducing weight improves fuel efficiency. For manufacturers of portable equipment, lightweight designs reduce user fatigue without compromising performance.

Durability That Stands Up to the Elements

The precision cutting process creates fibers with smooth, consistent surfaces that are not prone to wear, corrosion, or environmental damage. Products with this enhanced durability can withstand extreme conditions, such as high temperatures, chemical exposure, or mechanical stress, while maintaining their structural integrity. As a result, precision-cut fibers extend the lifespan of materials and perform reliably in various environments.

Versatility Across Industries

Precision-cut fibers are valuable across a wide range of industries because they are adaptable. Because of the fibers’ customizable properties, manufacturers can tailor the fibers to meet their needs, such as vibration dampening in automotive components or biocompatibility in medical devices. This flexibility, combined with their consistent performance, enables precision-cut fibers to meet the unique demands of diverse applications.

Beyond Strength and Durability

What about beyond the core strengths of precision-cut fibers? Here are some additional benefits that enhance their value in specialized and demanding applications.

Thermal Resistance

Precision-cut fibers often exhibit superior thermal management properties compared to conventional materials. The uniform structure allows for predictable thermal conductivity and expansion characteristics. These properties make precision-cut fibers ideal for applications involving temperature extremes or precise thermal control requirements.

Excellent Flexibility

Despite their strength and durability, precision-cut fibers have excellent flexibility. This combination of qualities is crucial for making products that can withstand repeated flexing or conform to complex geometries without compromising performance.

Electromagnetic Shielding

Many precision-cut fiber applications involve electromagnetic interference (EMI) shielding requirements. The consistent dimensions and properties of these fibers allow for predictable and effective electromagnetic shielding. This supports the creation of communication equipment for sensitive electronic applications.

What This Means for the Future of High-Performance Gear

Advances in precision cutting are unlocking new possibilities for high-performance materials. As techniques improve, fibers will become even lighter, stronger, and more precise. At the same time, emerging materials, such as bio-based or nanocomposites, could further expand their applications.

This progress paves the way for innovations like self-healing composites, materials with built-in sensors, and ultra-lightweight components for the aerospace and automotive industries. Precision-cut fibers are driving the next generation of high-tech solutions, and they will remain at the forefront of material innovation.

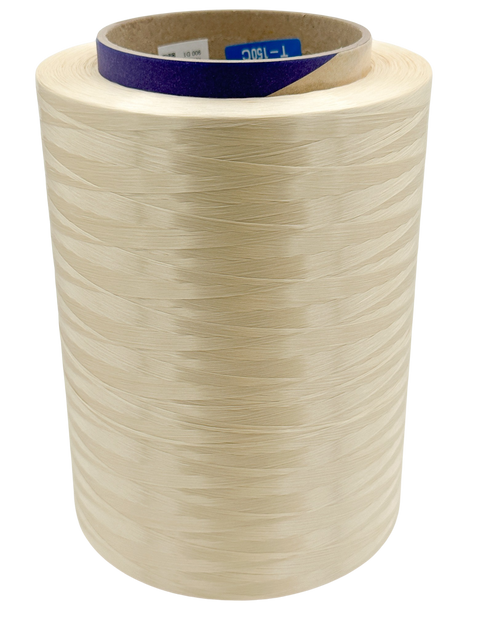

Rocket-Fibers—Your First Choice in Precision-Cut Fibers

Quality and reliability are nonnegotiable for our customers. That is why Rocket-Fibers is proud to provide high-quality precision-cut fibers. You can feel confident in our products and services because we carefully source our materials to meet the needs of demanding industries. Our commitment to excellence ensures each product delivers the strength, durability, and performance you require for your applications.

Choosing Rocket-Fibers gives you a trustworthy partner who prioritizes your success. With a focus on dependable services and expert guidance, we’re here to support your projects with materials that meet the highest standards. You can count on us to deliver precision and performance every time.

Precision-cut fibers represent the innovation and engineering driving industries forward. They set the standard for what’s possible in high-performance materials that redefine expectations. It’s easy to see why precision-cut fibers are the secret to high-tech gear, enabling solutions that help you overcome countless challenges. With these materials at your side, the future of your projects is endless.