Understanding the D/d Ratio in Cordage Applications

When working with high-performance ropes and cords, one of the most critical factors for performance and safety is the D/d ratio. This simple ratio plays a major role in determining rope life, bending fatigue, and overall system reliability.

Whether you’re using HMPE (Dyneema®), aramid fibers like Kevlar® or Technora®, or Vectran™ , understanding and applying the proper D/d ratio can save you costly downtime and extend the life of your cordage.

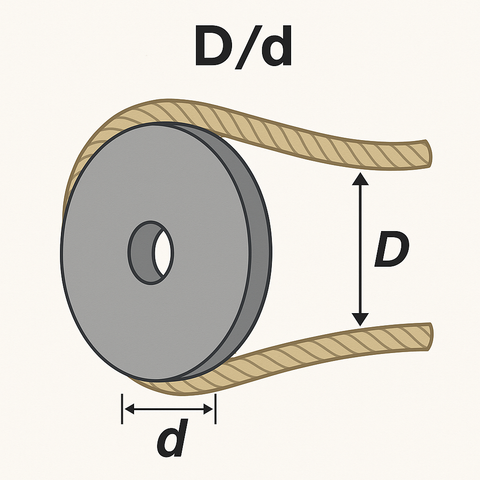

What is D/d?

The term D/d refers to the ratio between:

- D = Sheave, drum, or pin diameter

- d = Rope diameter

Formula:

D/d = Sheave Diameter (D) ÷ Rope Diameter (d)

Example:

If you have a 1.5 mm rope running over a 15 mm sheave:

D/d = 15 ÷ 1.5 = 10:1

Why Does the D/d Ratio Matter?

Every time a rope bends over a sheave, its fibers experience compression and tension. The tighter the bend (smaller sheave), the higher the stress, leading to:

- Shortened rope life

- Increased internal heat and fiber damage

- Potential for unexpected failure

Higher D/d ratios = Longer life, lower stress

Lower D/d ratios = Higher stress, faster wear

Recommended D/d Ratios by Fiber Type

| Fiber Type | Recommended D/d Ratio |

|---|---|

| UHMWPE (Dyneema®) | ≥ 8:1 (preferably 10:1+) |

| Polyester | ≥ 6:1 |

| Aramid | ≥ 10:1 |

Example: A 1.5 mm HMPE cord should run over a sheave at least 12 mm (8:1 minimum), though 15 mm (10:1) is ideal.

| Rope Diameter (mm) | Recommended Sheave Diameter (mm) |

|---|---|

| 0.5 | 4.0 |

| 1.0 | 8.0 |

| 1.5 | 12.0 |

| 2.0 | 16.0 |

| 2.5 | 20.0 |

| 3.0 | 24.0 |

| 3.5 | 28.0 |

| 4.0 | 32.0 |

| 4.5 | 36.0 |

| 5.0 | 40.0 |

| 5.5 | 44.0 |

| 6.0 | 48.0 |

| 6.5 | 52.0 |

Where Is D/d Critical?

- Winches & hoists

- Marine rigging

- Industrial lifting slings

- Theatrical rigging

- Robotics and motion control

- Aerospace cable routing

Rocket-Fibers Expertise

At Rocket-Fibers, we specialize in high-performance fibers and understand how details like D/d ratio impact real-world applications. We supply HMPE, Kevlar®, Technora®, Vectran™ , and other advanced fibers—along with guidance on proper design to optimize performance.

For more application insights, check out our Fiber Applications Blog.

Need help selecting the right cordage or determining the correct D/d ratio for your system? Contact Us today—we’re here to help.